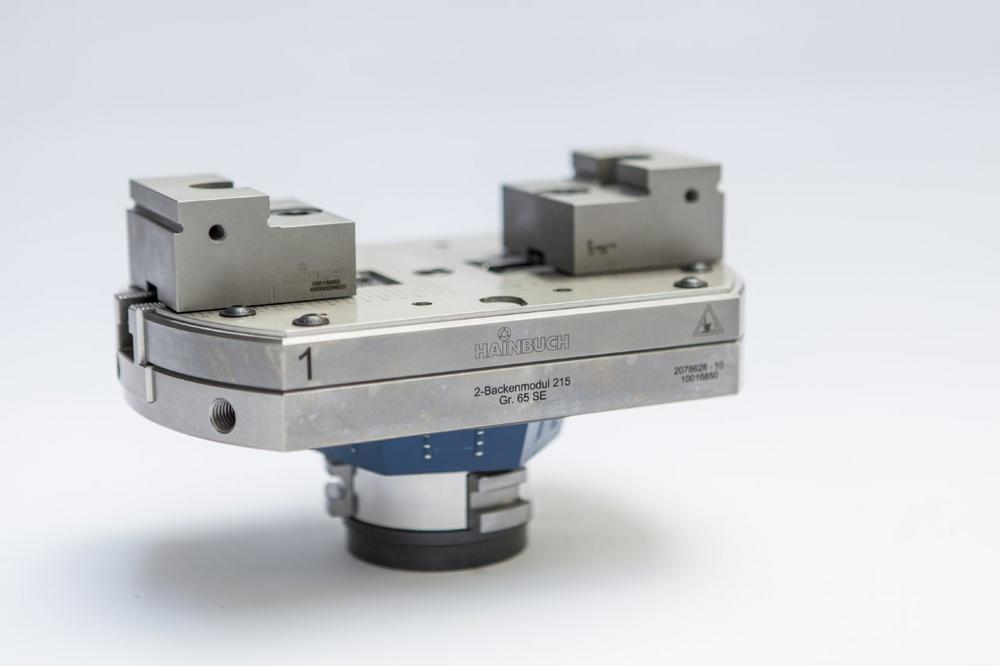

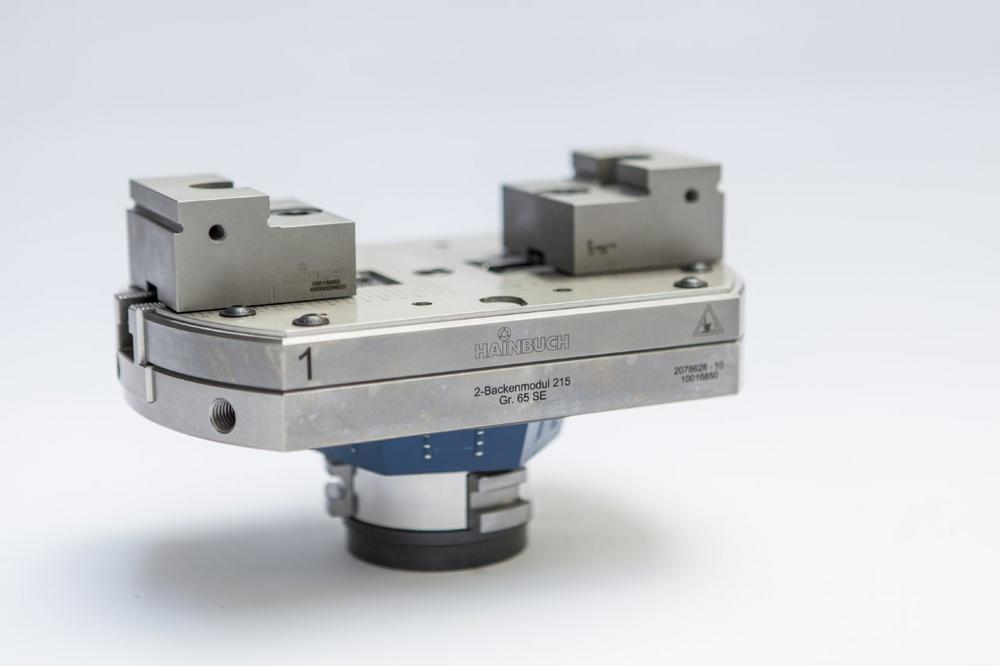

A new addition to the modular system family: the 2-jaw module. The small alternative to a large centric clamping vice

The modular system: designed for maximum flexibility

Round workpieces are clamped externally with classic clamping heads. But when these reach their limits, because a larger diameter of the workpiece needs to be clamped, then the 3-jaw module is used. And for cubic parts, the 2-jaw module is used for centric clamping in machining centers and milling machines. In just two minutes, it is possible to change-over from external clamping to centric clamping. The 2-jaw module can even be used at speeds of up to 1,500 rpm. Due to its small, lightweight design it is the perfect alternative to a large and heavy centric clamping device. The basic unit into which the jaw module is inserted is a Hainbuch chuck or vice. Modules can be exchanged without changing the clamping device and, thanks to the integrated Centrex quick-change interface, no alignment is needed.

Small, light and multitasking

The Hainbuch solution with its chucks or vices and jaw modules is nothing like the gigantic, heavy vices found in many shop floors, and whose size is more a drawback than an advantage. In practice this often leads to a large chuck holding a small workpiece. And this immediately causes a dilemma because it often means the tools are hard to access. It is not unusual to use special tools, but this comes with a very high risk of collision. By comparison, the Hainbuch modular system is far more efficient, and just as capable of multitasking as machine tools are nowadays.

HAINBUCH GmbH

Erdmannhäuser Str. 57

71672 Marbach

Telefon: +49 (7144) 9070

Telefax: +49 (7144) 18826

http://www.hainbuch.com

![]()