New solution from 4JET to quickly produce inner contours with the laser

Breaking News:

Donnerstag, Apr 25, 2024

Until now, the laser-based separation process used in PEARL systems was only suitable for processing glass along its subsequent outer contour. The reason for this is the "zero-gap cut" generated by this process, which does not allow the cut component to be detached in its entirety without cutting open the edge material at certain positions.

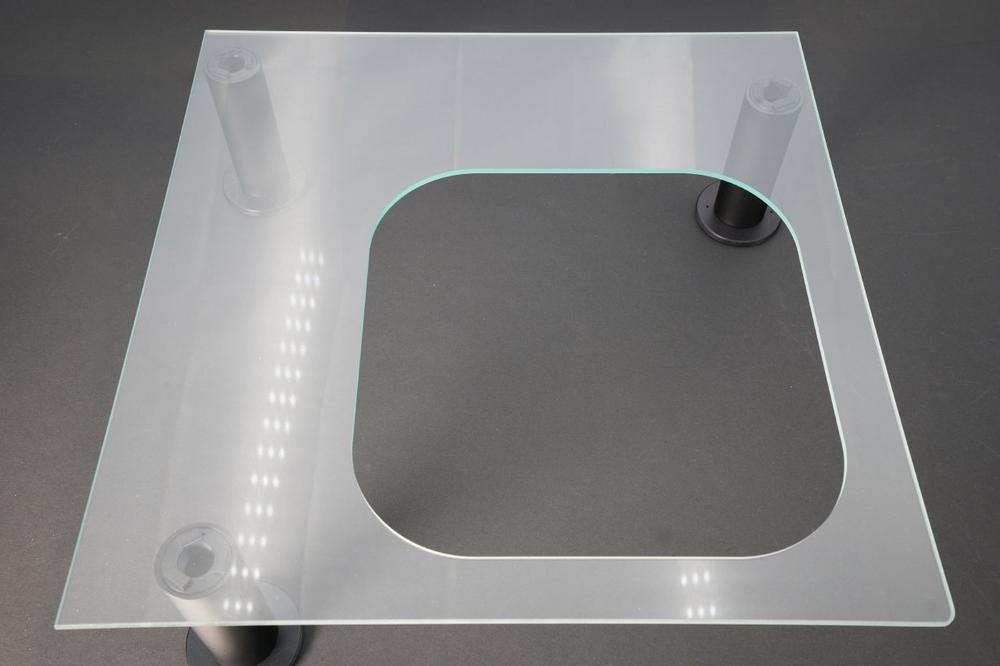

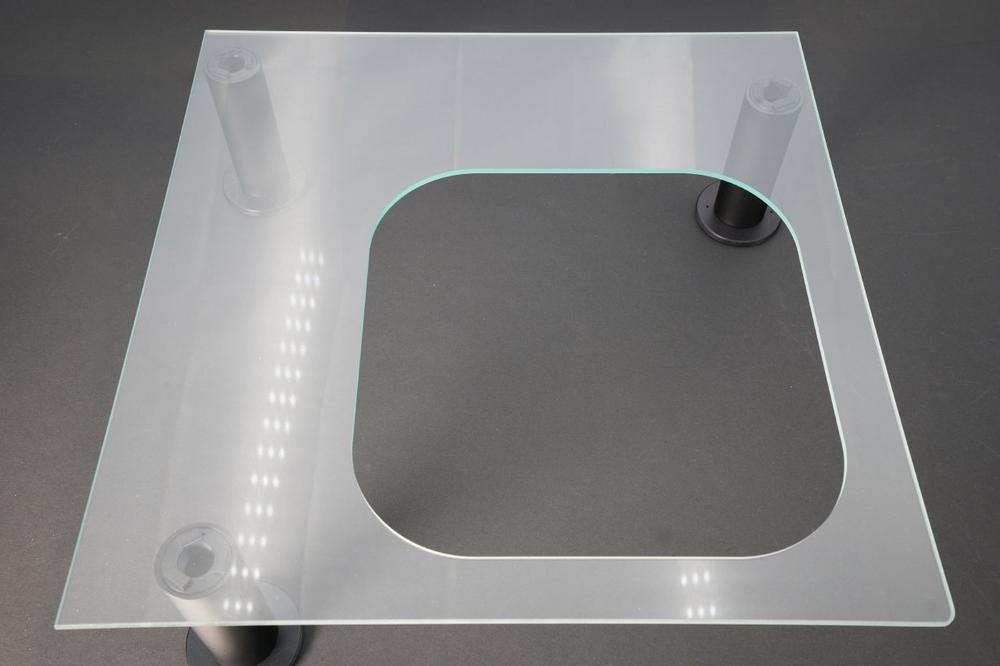

Further development now makes it possible to cut inner contours and to dissolve out the inner core. Filamentation of the glass is achieved at the well-known high cutting speed of up to more than 1 m/s. A downstream process allows the components to be dissolved out without any loss of quality. The process is highly productive – for example, the side sliding window for a small van can be dissolved out in less than 20 seconds. The separation process leading to success must be adapted once to the respective contour and the specific glass properties.

The new laser-based cutting process for interior contours is thus an ecological and cost-efficient alternative to conventional processes such as waterjet cutting

The 4JET Group delivers solutions for the surface technology of the future. The company was founded in 2006 and supplies all of the world’s leading tire manufacturers with tire marking, mold cleaning and adhesive preparation solutions, among others. Customers also include major OEMs and other automotive suppliers. The 4JET microtech business unit supplies laser micromachining systems for processing technical glass, solar cells and other high-tech components. Since August 2018, the company has been operating a job shop for laser processing in Prutting near Rosenheim. Subsidiaries in Shanghai and Atlanta provide sales consulting and technical services to international customers.

For more information, visit [url=http://www.4jet.de/en]www.4jet.de/en[/url].

The 4JET Group

Konrad Zuse Strasse 1

52477 Alsdorf

Telefon: +49 (2404) 9221-0

Telefax: +49 (2404) 9221-133

http://www.4jet.de

![]()