Industrial image processing for the plastics industry

Breaking News:

Mittwoch, Dez. 17, 2025

Machine vision methods have been widely used in industry for many years – particularly in quality control and automation. With the increasing use of AI-based analysis methods, even highly complex applications can be realized today. However, this still requires the targeted selection of suitable illumination setups and the optimal choice of acquisition parameters.

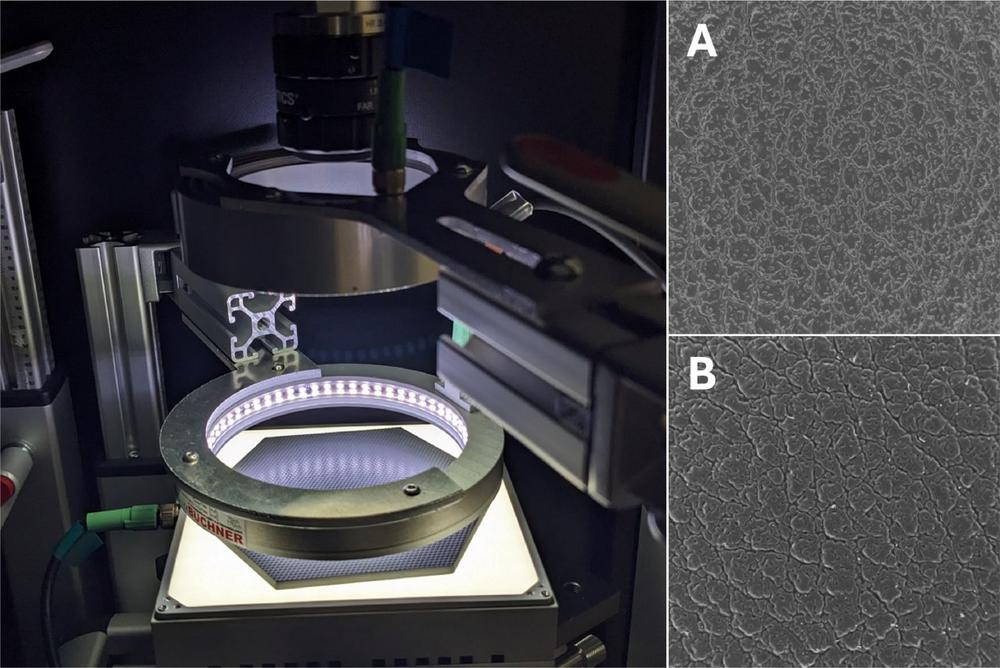

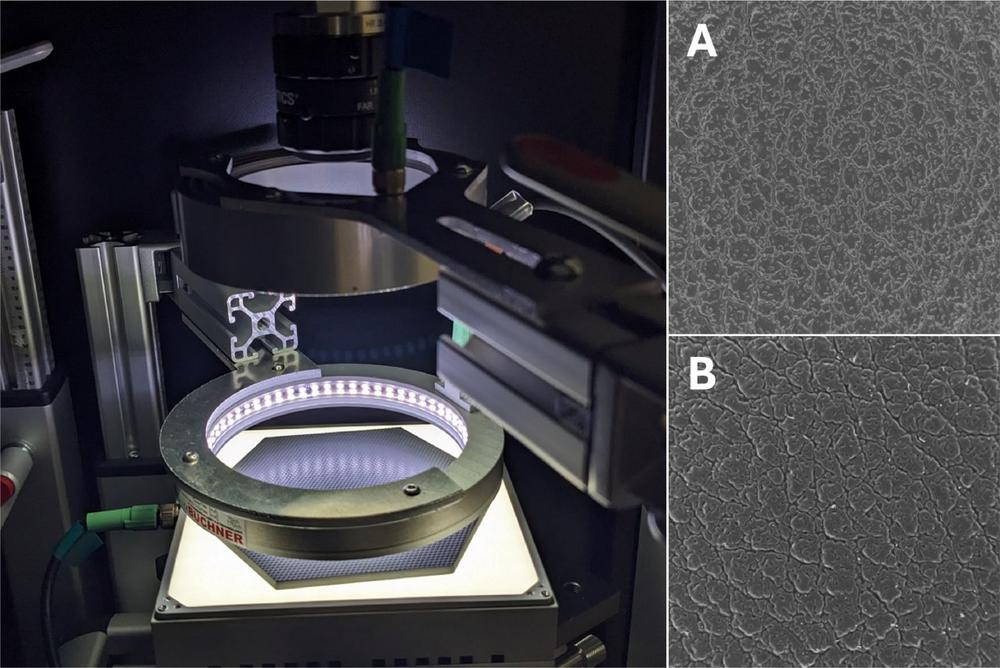

Since early 2025, the Spectroscopy working group at SKZ KFE gGmbH has been operating a new camera inspection system that enables a wide range of variable lighting situations – even in combination with several types of light. The large measuring chamber, which is primarily used to shield external light, houses a high-resolution monochrome camera. In conjunction with a selection of high-quality, quick-change lenses, the smallest structures below 50 µm can be captured and analyzed in great detail with a large field of view (approx. 100 x 100 mm²).

Four different types of illumination are available, which can be used for a variety of inspection tasks – such as the detection of defects (e.g. scratches, cracks, streaks, inclusions) in injection-moulded components or granulates as well as for surface characterization:

“In addition to the installed components, the integrated programming interface is particularly useful in our day-to-day research,” explains Michael Dold, Scientist Spectroscopy. “It allows individual software control and direct evaluation – also with the help of modern AI-supported methods.” Dold is convinced: “We are confident that we will also gain valuable insights with the new system in future projects.”

The SKZ is a climate protection company and a member of the Zuse Association. This is an association of independent, industry-related research institutions that pursue the goal of improving the performance and competitiveness of industry, especially SMEs, through innovation and networking.

SKZ – Das Kunststoff-Zentrum

Friedrich-Bergius-Ring 22

97076 Würzburg

Telefon: +49 931 4104-0

https://www.skz.de

![]()