Large-area inline fault detection with thermography

The challenge in manufacturing high-quality plastic products often lies in the low tolerances for surface quality and internal defects. To meet the highest quality standards and avoid potential product complaints, comprehensive quality control integrated directly into the ongoing process is becoming increasingly important.

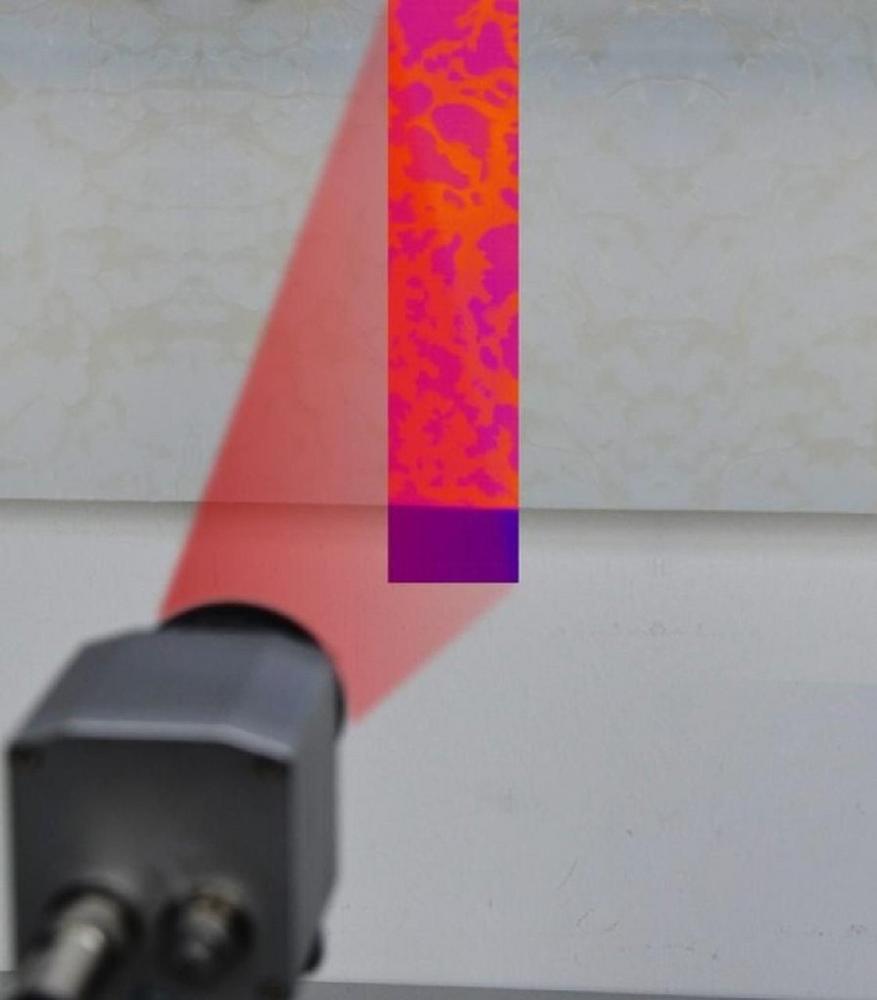

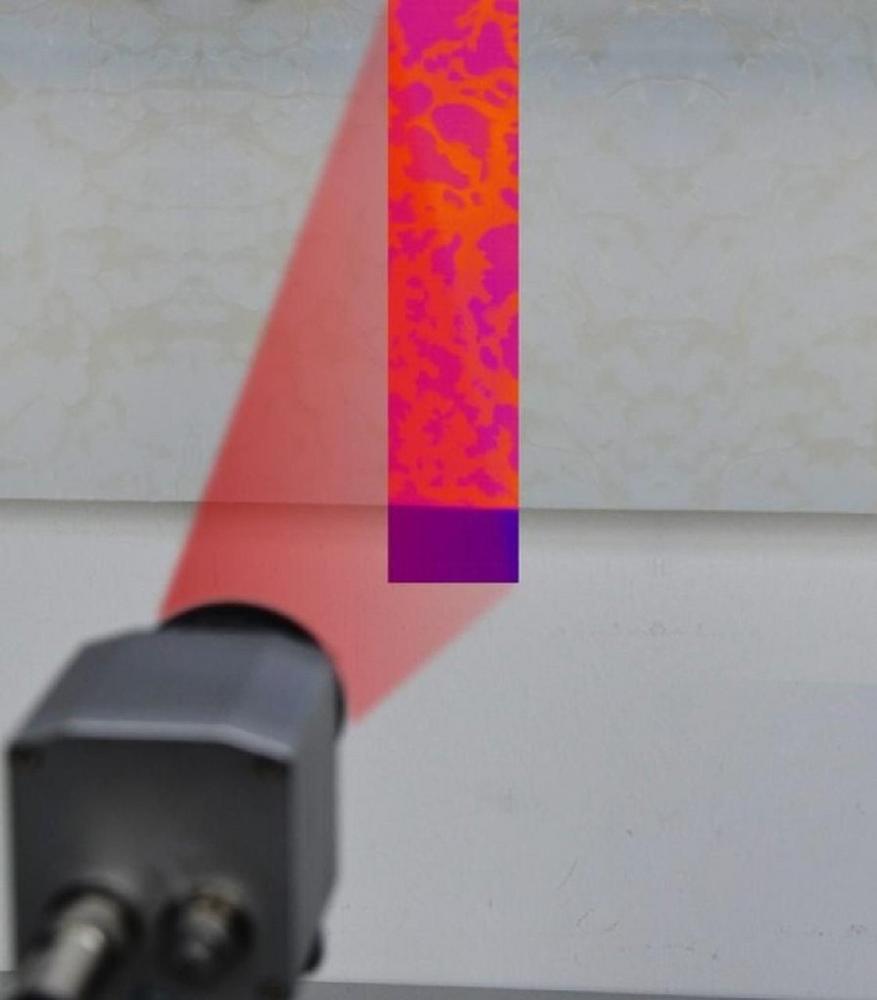

SKZ presents a thermography measurement system based on a proven method. Either the manufacturing-related heating and cooling of the plastic products is used passively, or active heating is induced to make defects in the product visible thermographically. The system allows inline monitoring and achieves up to 100% control depending on the product.

Compared to conventional optical camera systems, the thermographic measurement system offers a robust solution that works independently of environmental conditions such as inhomogeneous illumination. The viewing angle plays a minor role, and even internal defects away from the surface are reliably detected.

Technically speaking, the system uses infrared thermography to perform precise temperature measurements on the surface. By analyzing the temperature distribution, not only surface defects such as streaks or dents can be detected, but also internal defects such as pores or foreign material inclusions. The high resolution and accuracy of thermography ensure reliable detection of even the smallest defects.

The SKZ has many years of extensive experience in thermography and offers companies support in implementing customized solutions. The institute accompanies the entire development process, from feasibility studies and integration into the production chain to training, maintenance, and support.

As an active member of the Zuse community, SKZ is committed to continuous innovation and networking in order to strengthen the performance and competitiveness of industry, especially small and medium-sized enterprises. The new thermography solution marks a significant advance in quality control and paves the way for efficient and precise production monitoring.

The SKZ is a climate protection company and a member of the Zuse Association. This is an association of independent, industry-related research institutions that pursue the goal of improving the performance and competitiveness of industry, especially SMEs, through innovation and networking.

SKZ – Das Kunststoff-Zentrum

Friedrich-Bergius-Ring 22

97076 Würzburg

Telefon: +49 931 4104-0

https://www.skz.de

![]()