The Next Step in Scaling up Perovskite PV with Linear Thermal Evaporation for High-Volume Manufacturing

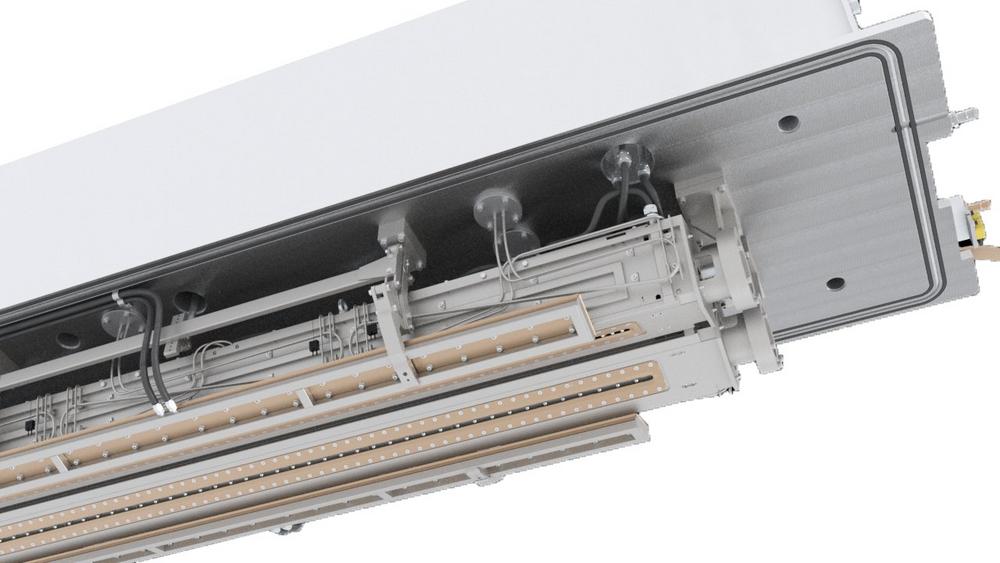

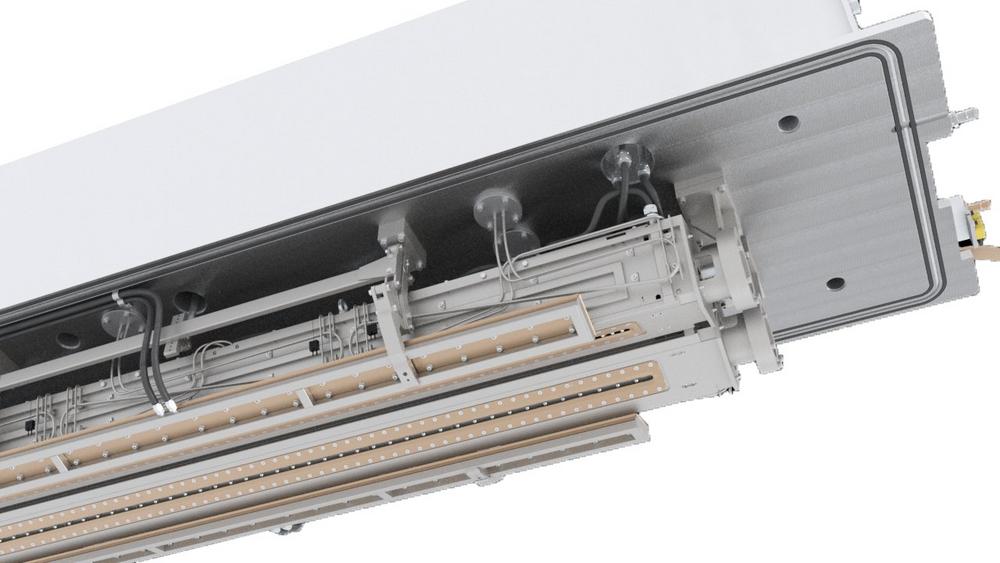

In this article, we will focus on the advanced design of VON ARDENNE linear evaporators and describe their unique features. A schematic design of a linear evaporator is shown above to explain the main consisting parts. (Figure 2)

The target material is filled as a powder in a crucible. The large crucible volume of the linear evaporators ensures long production cycles. Furthermore, the linear evaporator design guarantees a large evaporation surface as a large area is exposed to the heating system.

Since the crucible is heated homogeneously, the material will start to evaporate when the material-specific melting temperature is exceeded. Or, for subliming materials, the vapor is emitted from the solid phase. The amount of material vapor that is released increases with the evaporation surface area and with increasing temperature following the “Clausius-Clapeyron Equation”.

The crucible is gas-tightly connected to the likewise homogeneously heated distribution system. By a suitable choice of tube diameter and nozzle system limiting the outflow, the material vapor can be distributed homogeneously over long distances with negligible pressure changes.

As a cold substrate is transported continuously under the material flow of the nozzle system, the arriving particles condensate on the substrates, which are either wafers or glass. The particles form a uniform coating on an area defined by the width of the nozzle system and, theoretically, an undefined length.

The precise and reproducible control of the resulting film thickness is realized by a Quartz Crystal Monitor (QCM) within the linear evaporation system. The QCM sensitively measures the deposition rate of the coated material. It serves as reference signal for reproducible and stable control by either power or temperature adaption.

Thus, we distinguish between low, medium and high-temperature-range linear evaporator sources. All systems ensure a fast and reliable PID-controlled heating up and cooling down with low overshooting to protect temperature sensitive materials from thermal stress.

Moreover, industrial campaign times can be achieved by

Click here to learn more or to get in touch.

VON ARDENNE develops and manufactures systems for the industrial vacuum coating of materials such as glass, wafers, metal strips, or polymer films. Depending on the application, these layers are one nanometer to a few micrometers thin and impart new functional properties to the surfaces. The coated materials serve as the basis for products such as architectural glass, solar modules, or touch screens.

VON ARDENNE is a leading provider of architectural glass coating systems and coating systems for thin-film photovoltaics. As a globally operating family business with branches in China, Japan, Malaysia, Taiwan, and the USA, VON ARDENNE focuses on customer proximity to provide ideal on-site service. VON ARDENNE systems are in use in more than 50 countries.

VON ARDENNE GmbH

Am Hahnweg 8

01328 Dresden

Telefon: +49 (351) 2637-300

Telefax: +49 (351) 2637-308

http://www.vonardenne.de

![]()