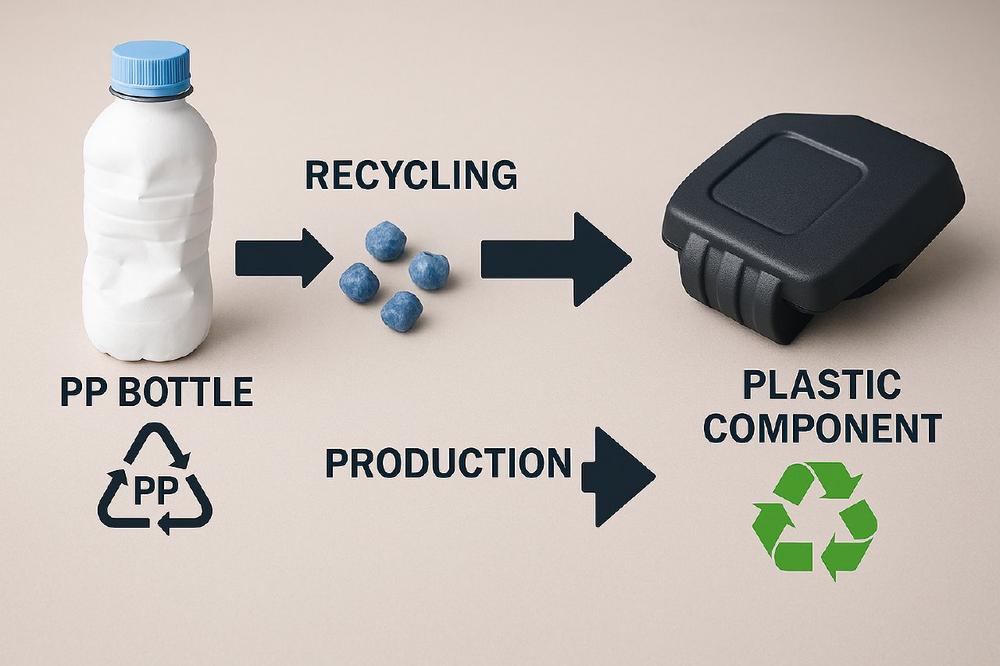

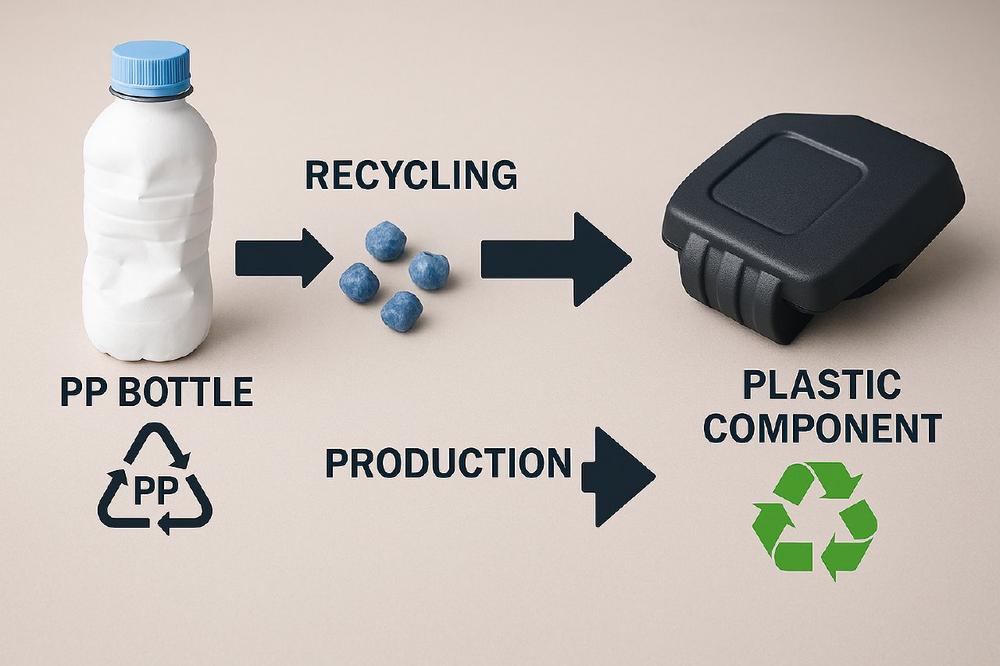

New fields of application for recycled plastics in technical components

Breaking News:

Dienstag, Okt. 14, 2025

In automotive engineering, recycled materials are currently used primarily in wheel arch liners, underbody panelling and boot linings. However, they are still rarely found in functional or thermally highly stressed areas such as the engine compartment, mechanical engineering or electrical engineering. The reason for this lies in the high requirements for temperature resistance, media resistance and long-term stability.

"There are currently still significant hurdles to the use of recycled materials in areas with continuous operating temperatures above 120 °C or in contact with oils and coolants. This is precisely where our new pioneering project comes in," explains Dr Oliver Tröppner, group leader for materials development and testing at the SKZ Plastics Centre.

From materials research to component testing

The industry-funded pioneering project takes a holistic approach: Suitable recycled materials are identified, their suitability for demanding technical components is evaluated, and solutions for industrial implementation are developed. Activities range from systematic material research and market analysis to the manufacture of reference components in injection moulding, extrusion and flexible applications, and practical tests under real operating conditions. Thermal, mechanical, media-related and long-term stresses are examined, as are in-depth material and component tests. The project is supplemented by recommendations for action and life cycle assessments, which provide companies with concrete design guidelines and an objective evaluation of recyclate performance. The project is scheduled to start in spring 2026 and will run for three years.

EU Green Deal – growing pressure on companies to act

The European Commission’s proposal for a new end-of-life vehicle regulation is increasing the pressure to act. From 2030, at least 25% of plastic parts in new vehicles must be made from PCR (post-consumer recycled material), 25% of which must be from closed-loop recycling.

‘For small and medium-sized enterprises in particular, the project is an opportunity to build up expertise at a manageable cost,’ emphasises Tröppner. ‘Those who address the technical possibilities and limitations of recycled materials at an early stage will secure clear competitive advantages and can strategically prepare for upcoming market and legal requirements,’ Tröppner continues.

About SKZ pioneer projects

SKZ pioneer projects are jointly financed by several companies. The results are available exclusively to the participating companies and are not published. The aim is to develop practical solutions that can be used individually.

The SKZ is a climate protection company and a member of the Zuse Association. This is an association of independent, industry-related research institutions that pursue the goal of improving the performance and competitiveness of industry, especially SMEs, through innovation and networking.

FSKZ e. V.

Friedrich-Bergius-Ring 22

97076 Würzburg

Telefon: +49 931 4104-0

https://www.skz.de

![]()