Eplan Smart Sourcing: checking device availability during the engineering phase

Breaking News:

Endeavour Silver startet Emission von vorrangigen Wandelanleihen

Eplan Smart Sourcing: checking device availability during the engineering phase

SMS group expands aluminum processing at GARMCO through modernization of the hot rolling mill

More transparency in engineering: perfectly synchronised component changes

Montag, Dez. 1, 2025

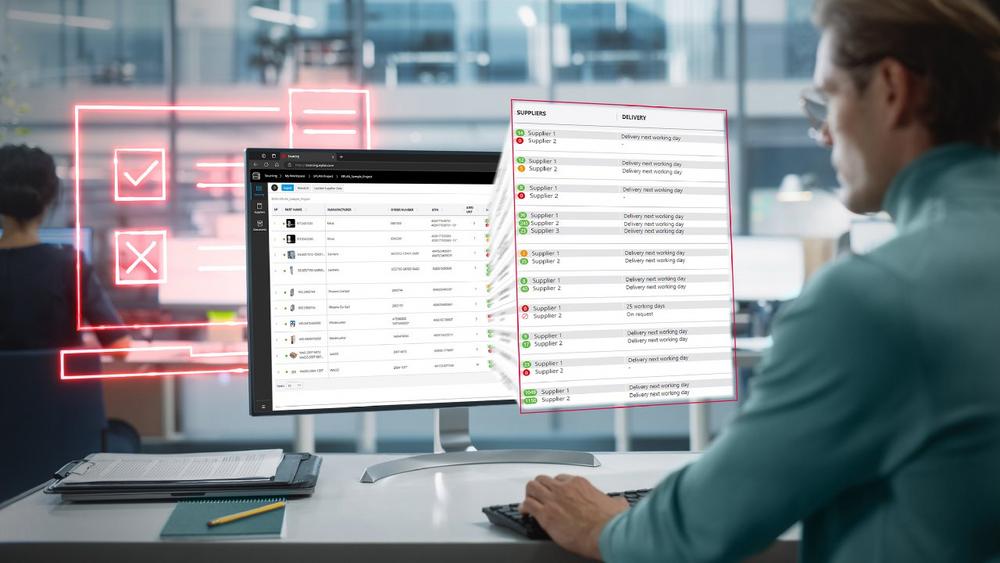

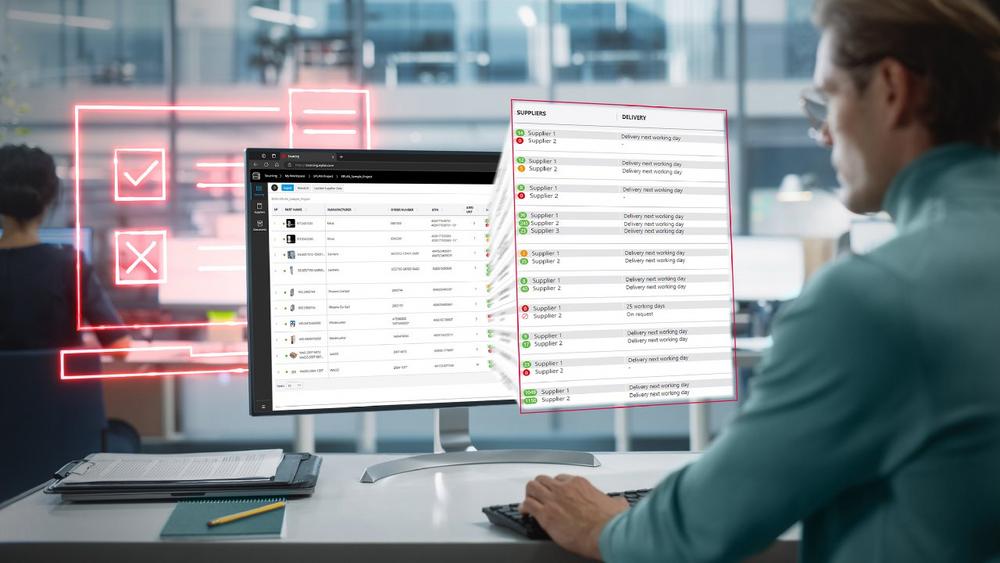

When designers start a new electrical engineering project, they often use templates from previous jobs as a blueprint. Copy and paste is a common way of working, but it does pose challenges. The previously used devices aren’t always available, and some of them have long delivery times. To ensure the process doesn’t come to a standstill – for instance when the purchase order is placed – in the future users will be able to check the availability of devices early in the electrical engineering phase using Eplan Smart Sourcing. This will be based on linking the systems of manufacturers and distributors (online shops, for instance), which offer direct access to logistical information. When an Eplan user makes an enquiry, a table using a traffic light display system shows the availability, current stock levels and delivery times for the items from their suppliers.

Projects made even faster

Eplan Business Owner for Data Driven Business Solutions (DDBS) Maurice Molinari explains: “Eplan Smart Sourcing allows design engineers to check very early in the process whether all items will be available at the planned delivery date. If a component isn’t in stock or can’t be delivered in time, they can already choose an alternative for the design. Discontinued components can be replaced by their current versions. This saves unnecessary, repeated coordination with procurement at a later stage when ordering components.” A requirement for this to work is that the component manufacturer or distributor is connected to Eplan Smart Sourcing.

Purchasing from the customer’s site also benefits from an optimised procurement process, as it has already been checked whether the parts planned to be used are still being manufactured and are available. Furthermore, if desired, procurement can simply select the bill of materials or selected items in Eplan Smart Sourcing, transfer them to the supplier’s online shop and efficiently initiate the ordering process.

Benefits for users:

A real game changer for suppliers

Component manufacturers and distributors also benefit from linking to Eplan Smart Sourcing. Early in the engineering phase, they can better assess their customers’ needs in a strategic way and adjust their inventories accordingly. Maurice Molinari: “With Eplan Smart Sourcing, manufacturers and distributors gain access to their customers at a much earlier stage in the value chain. This make it easier to forecast demand and plan overall portfolios. Ultimately, the manufacturer is directly networked with its customer via the software and thereby gains greater visibility.” The first distributors such as Alexander Bürkle and manufacturers such as Rittal are already connected for the SPS. Solutions provider Eplan is currently in talks with many key players who have already expressed an interest in participating.

Development continues

Eplan Smart Sourcing is being previewed in Nuremberg and manufacturers and distributors on the German market are being actively encouraged to discuss opportunities for participation at the trade fair. The launch for Smart Sourcing in Germany is planned for 2026 – and naturally the more manufacturers and distributors connected to the system, the greater the benefits for the end users. The software will also be further expanded. It is conceivable that ERP systems will be linked to it, or that alternative or more current versions of the items will be suggested if components are unavailable.

In conclusion

The coming preview of Eplan Smart Sourcing has opened up a discussion, and dialog with component manufacturers and distributors will continue at the SPS with the aim of involving as many relevant key players as possible in the run-up to the launch in 2026.

Eplan provides software and service solutions in the fields of electrical, automation and mechatronic engineering. The company develops one of the world’s leading design software solutions for machine and panel builders. Eplan is also the ideal partner to streamline challenging engineering processes.

Both standardised as well as customised interfaces to ERP and PLM/PDM systems ensure data consistency along the whole value chain. Working with Eplan means boundless communication across all engineering disciplines. No matter whether small or large enterprises: Customers can apply their expertise more efficiently. Worldwide, Eplan supports 73,100 customers. Eplan wants to grow further with customers and partners and pushes integration and automation in engineering forward. Within the Eplan Partner Network, open interfaces and seamless integrations are realised together with partners. „Efficient engineering“ is the focus.

Eplan was founded in 1984 and is part of the owner-operated Friedhelm Loh Group. The group operates worldwide, with 13 production sites and 95 international subsidiaries. It has 12.600 employees and posted revenues of €3,1 billion euros in fiscal 2024. In 2023, the Friedhelm Loh Group was presented with the “Best Place to Learn” and “Employer of the Future” awards.

For more information, visit www.eplan-software.com and www.friedhelm-loh-group.com.

EPLAN GmbH & Co. KG

An der alten Ziegelei 2

40789 Monheim

Telefon: +49 (2173) 3964-0

Telefax: +49 (2173) 3964-25

http://www.eplan.de

![]()