faigle at LogiMAT 2026: Rethinking plastics – for next-generation intralogistics

Reliable, efficient and sustainable: faigle keeps global material flows running smoothly.

The product of in-depth materials expertise, distinctive engineering capabilities and close customer partnerships, faigle’s long-lasting, energy-efficient and low-noise plastic solutions play a key role in optimising material flows in conveying, sortation and storage systems the world over.

At LogiMAT 2026, faigle Kunststoffe GmbH will be showcasing its groundbreaking plastic solutions for automated intralogistics systems. For decades now, faigle – an international family-run business – has been developing and manufacturing high performance components made from engineering plastics for intralogistics applications.

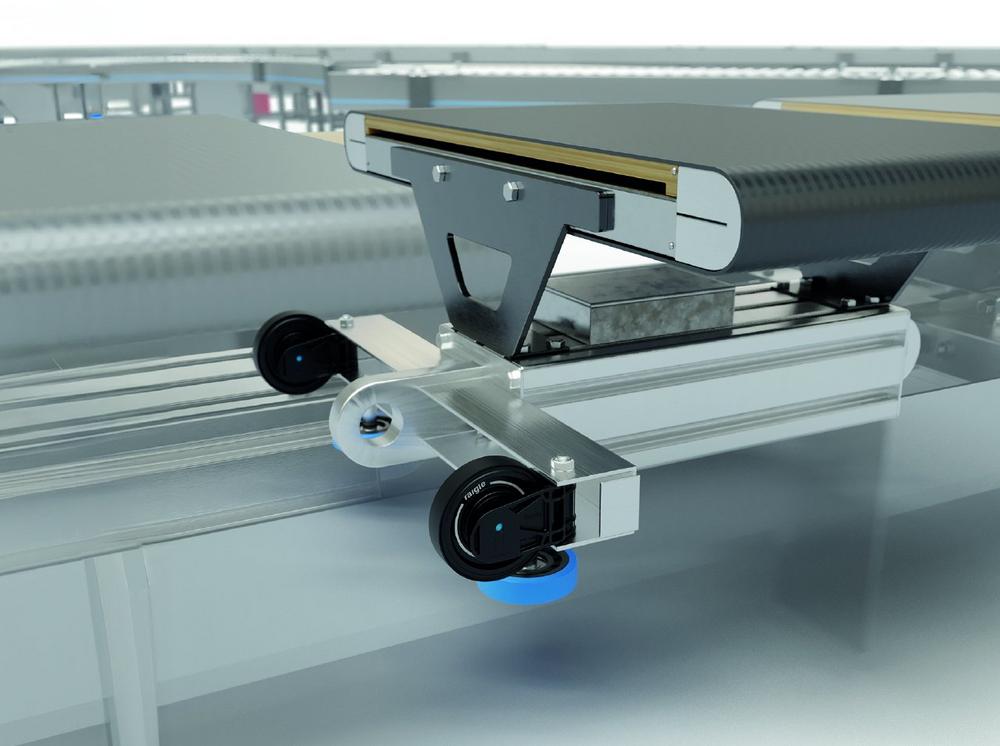

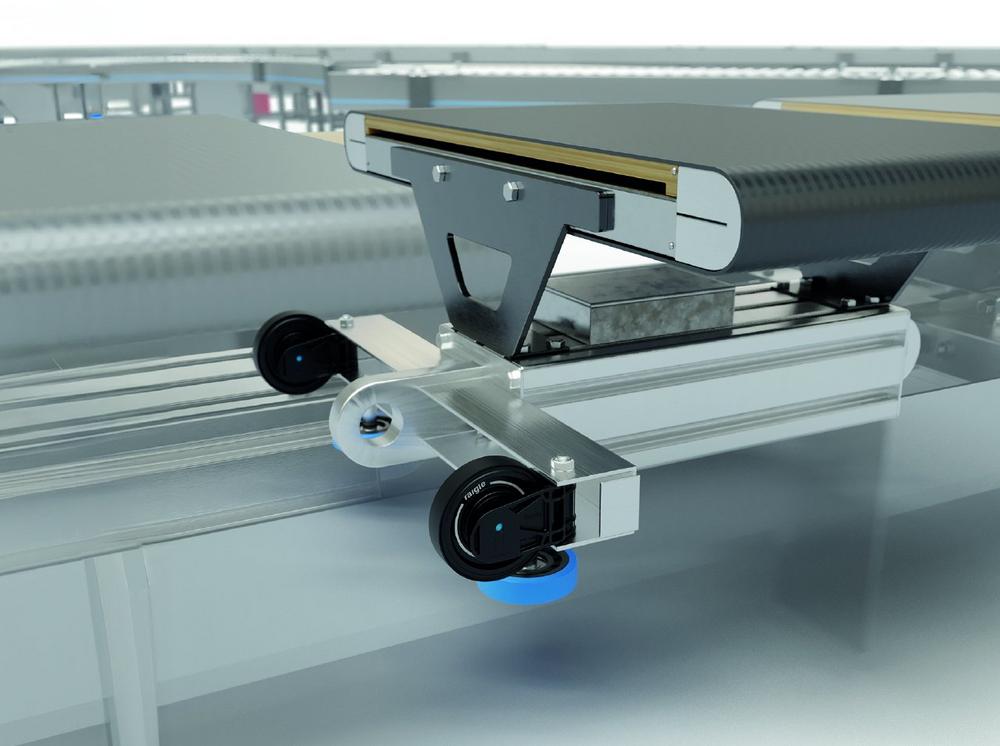

faigle’s current portfolio will be on display at the event, including ultra-light wheel holders, low-noise sorter running wheels with integrated damping system, highly robust support and guiding rollers, as well as specialised solutions for autonomous mobile robots (AMRs) and shuttle systems. The faigle ecoWheel – the industry’s first climate-friendly running wheel – is a clear statement of intent: combining the highest technical performance standards with the use of bio-based and recycled raw materials, the ecoWheel shows that sustainability and outstanding performance are not mutually exclusive.

The portfolio is aimed primarily at intralogistics system developers, purchasers and operators, as well as service staff and sustainability officers – professionals who are targeting reliable, low-noise and energy-efficient storage and conveying system operations.

The challenge: faigle Engineering Sprint

Through its Engineering Sprint project, faigle is out to show what radically simplified, modular plastic solutions with optimised lightweight designs might look like if they were developed in the space of just a few weeks – and without any constraints on new ideas. The initiative is designed to send a clear message to system producers: faigle doesn’t just specialise in components, it can also completely redefine entire assemblies – boldly, quickly and with tangible results.

What exactly was the end result?

faigle will reveal all at LogiMAT 2026. You’re in for a surprise!

Visit faigle at LogiMAT 2026:

Messe Stuttgart, Hall 5, stand A02

24-26 March 2026

Expertise in motion

The faigle Group

An international company with sites in Europe and Asia, the faigle Group specialises in the development and production of high-quality components and assemblies made from engineering polymers. We use state-of-the-art manufacturing technologies – including injection moulding, as well as PU and PA casting and machining – to create innovative and durable plastic solutions for a wide range of industries.

As a reliable partner for our customers, we provide support from the initial idea and development right through to volume production. Our experienced team of materials experts, plastics engineers and mechanical engineers works continuously to develop innovative solutions and custom innovations in consultation with our customers. Our R&D centres in Europe and Asia work closely with our customers to create optimised solutions that generate added value.

Thanks to our modern equipment, flexible production capacities and comprehensive technical expertise, we can handle small, medium and high-volume production runs with maximum efficiency. And we have a proven record as a stable, high-performance supplier – even in challenging economic times.

What drives us? Drawing on our passion and constantly growing expertise, we take steps designed to continuously optimise our technologies, with the aim of creating sustainable and innovative solutions for demanding industrial applications.

faigle – moving forward.

faigle Group – facts and figures

Founded: 1947

Employees: 363

Revenue, 2024: EUR 71m

Business purpose: Developing and producing engineering plastics solutions, plastics processing and trading in semi-finished plastic products

Divisions: Plastic products and plastics solutions for passenger movement (escalators, moving walks and elevators), intralogistics, railways, mechanical and plant engineering, and custom solutions for industry

Locations: faigle Kunststoffe GmbH (Hard, AT)

faigle Industrieplast GmbH (Hard, AT)

faigle Igoplast AG (Au, CH)

Suzhou faigle Engineering Plastics Co., Ltd. (Suzhou, CN)

Group Executive Board: faigle Group GmbH (Hard, AT) – Wolfgang Faigle, Friedrich Faigle, Roland Bartenbach

Owners: Faigle family

Export ratio: 72%

faigle Kunststoffe GmbH

Landstraße 31

A6971 Hard

Telefon: +43 (5574) 6811-0

Telefax: +43 (5574) 6811-55

http://www.faigle.com

![]()