Important step for the energy transition

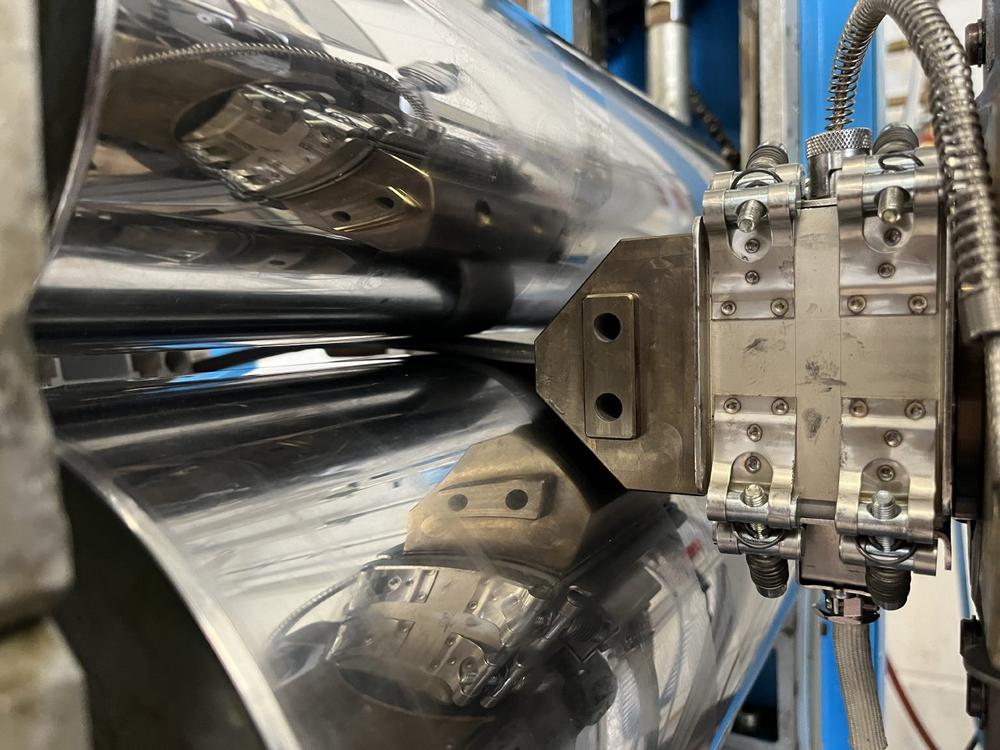

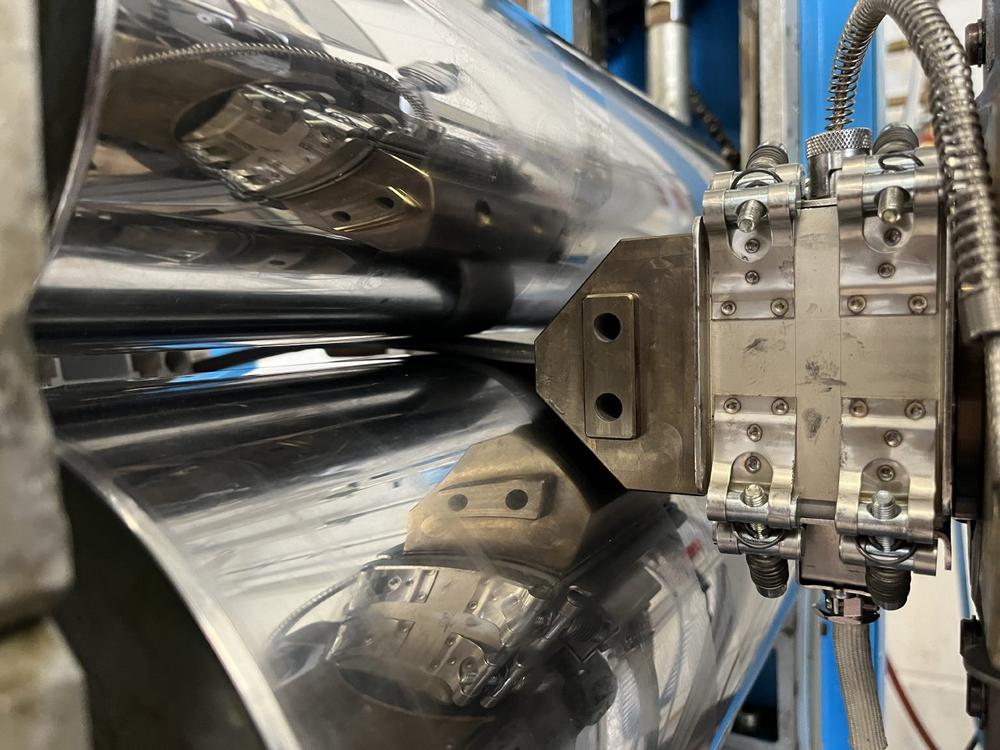

Under the leadership of Frederik Hellert, Scientist Networked Materials at SKZ, and in cooperation with ENTEX Rust & Mitschke GmbH (Bochum), SKZ successfully completed a project funded by the Federal Ministry for Economic Affairs and Climate Protection in August 2025. The aim was to develop a continuous direct extrusion process for the production of bipolar plates for high-temperature hydrogen fuel cells. These plates consist of a highly filled epoxy resin compound with graphite and carbon black and must be thermally and electrically conductive as well as gas-tight.

Efficiency through material innovation and process integration

The project demonstrated that extruded plates with a filling degree of 80 per cent by weight exhibit sufficiently high conductivity after pressing. The targeted addition of carbon black further increased electrical conductivity significantly. At the same time, it was possible to produce mechanically stable and dense plates even in the continuous extrusion process – an important step towards industrial series production.

Project manager Hellert emphasises the significance of the project: ‘The direct extrusion of highly filled materials for fuel cell components opens up completely new avenues in production – efficient, cost-effective and with impressive performance. These are exactly the kinds of developments we need to make fuel cell technology fit for the mass market.’

The SKZ would like to thank ENTEX Rust & Mitschke GmbH for its partnership and technical expertise, which contributed significantly to the success of the project.

The SKZ is a climate protection company and a member of the Zuse Association. This is an association of independent, industry-related research institutions that pursue the goal of improving the performance and competitiveness of industry, especially SMEs, through innovation and networking.

SKZ – Das Kunststoff-Zentrum

Friedrich-Bergius-Ring 22

97076 Würzburg

Telefon: +49 931 4104-0

https://www.skz.de

![]()