Bluhm Systeme showcases marking solutions for intralogistics at LogiMAT 2026

Donnerstag, Jan. 15, 2026

Hall 2, Booth 2A05

From March 24 to 26, 2026, Bluhm Systeme GmbH will present state-of-the-art marking systems using labels, ink, and laser technology specifically designed for intralogistics at LogiMAT. The exhibits will be on display in Hall 2, Booth 2A05 at the Stuttgart trade fair grounds.

At LogiMAT, Bluhm Systeme demonstrates how modern marking technology contributes to greater efficiency in intralogistics processes across industry, manufacturing, and logistics centers. Clear and reliable identification of goods, load carriers, and components ensures transparent material flows that can be precisely controlled. Printed or applied codes, labels, and laser markings enable automatic identification, tracking, and assignment of products throughout the entire intralogistics process.

Automated marking

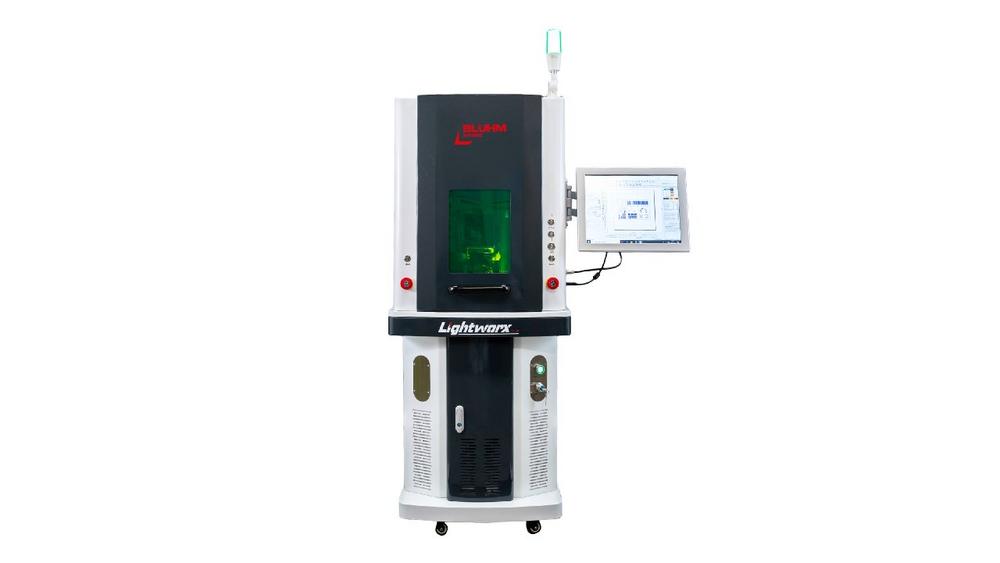

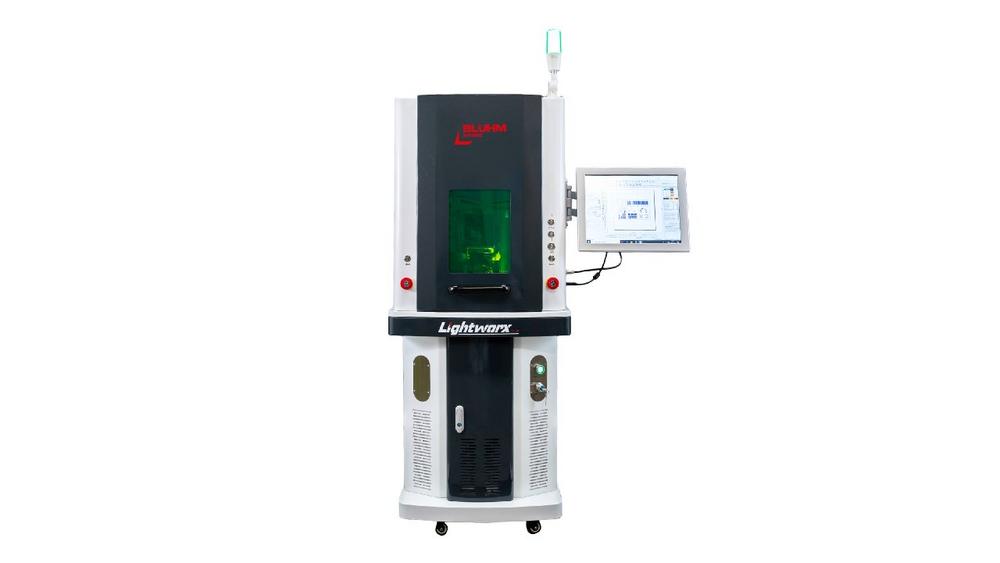

To meet these requirements, Bluhm Systeme relies on automated marking solutions that can be flexibly adapted to a wide range of processes. Depending on the application, inkjet printers, laser marking systems, or labeling solutions are used. The modular systems are designed for space-saving integration into existing production and conveyor lines and can be combined with industrial robotics. Automation software ensures seamless connectivity, supports process monitoring, and enables targeted error analysis as well as remote access independent of location. At the same time, ease of use and low maintenance are key priorities to ensure smooth day-to-day operation.

A wide range of marking technologies for intralogistics applications

Visitors are invited to experience Bluhm Systeme’s marking solutions in practical demonstrations at the booth and to learn more in Hall 2, Booth 2A05.

Bluhm Weber is a leading provider of industrial labelling technology. The product portfolio includes inkjet printers, laser markers, labelling systems and thermal transfer printers. The systems mark products, packaging and pallets across all industries with ink, laser and labels. A dedicated team develops, manufactures and distributes the innovative product range at the company headquarters in Rheinbreitbach/Rhineland-Palatinate. With eight branches in Europe and internationally networking sales partners, Bluhm Weber is known nationally and internationally as an expert in coding and labelling. Labels are also produced in the company’s own label printing plant. Customised services, supporting Industry 4.0 software and consumables round off the portfolio as a full-service provider. Bluhm Weber stands for reliability, innovation and customer proximity.

Bluhm Systeme GmbH

Maarweg 33

53619 Rheinbreitbach

Telefon: +49 (2224) 77080

Telefax: +49 (2224) 7708-20

http://www.bluhmsysteme.com

![]()